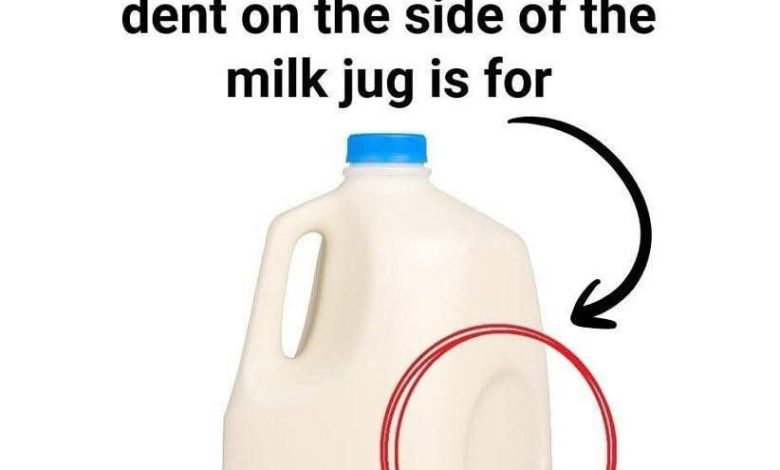

That indentation isn’t an accident. It’s an intentional part of the jug’s design, created for safety, durability, and strength.

1. It Helps Manage Pressure

Milk is a liquid, and liquids react to temperature changes. Since milk has to stay cold, any shift in temperature—like going from a warm delivery truck to a cold fridge—causes the liquid to expand or contract.

Without it, the jug could bloat, crack, or even burst (especially if the milk freezes). The dent gives the plastic room to adjust—like the jug’s built-in stress reliever.

2. It Reduces Spills

Ever dropped a jug of milk? Same here.

That dent also works like a shock absorber. If the jug gets bumped or dropped during transport, stocking, or grocery-store handling, the indentation helps absorb the impact.

This lowers the risk of cracks and leaks—saving you from a messy kitchen disaster and saving companies money from damaged products.

3. It Strengthens the Jug Without Extra Plastic

The dent is an engineering shortcut that adds durability without increasing plastic use.

Think of the support arches in architecture—they add strength using shape, not weight.

The indentation reinforces the structure of the jug, allowing it to stay sturdy while remaining lightweight and inexpensive to produce. Clever, efficient design at its best.

⚠️ A Warning Sign for Spoiled Milk

Here’s an interesting twist: sometimes, if milk spoils, bacteria inside the jug produce gas. This gas builds pressure and can cause the dent to bulge outward.

If you notice a milk jug where the dent is puffed out or looks strange, take it seriously—it may be a sign the milk has turned.

(Not every bulge means spoiled milk, but it’s a good early warning.)

Why a Circle?

Circles handle pressure best. With no sharp corners to concentrate stress, pressure distributes evenly around the edge. That makes the circle perfect for an area designed to flex with temperature changes and handling.

Plus, circles are easy to manufacture consistently. Simple, strong, and efficient.

Continue reading…